REF : DEGARCASE-3001

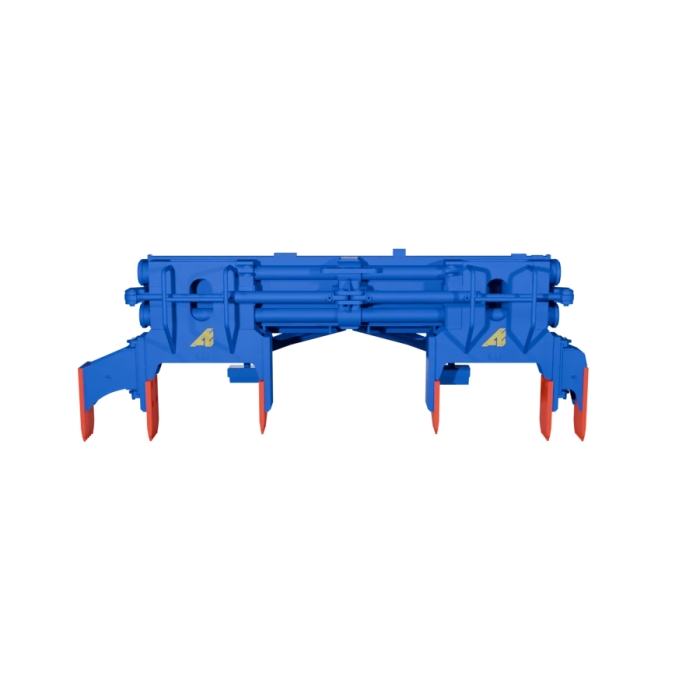

BALLAST TRACK REMOVER

The ballast cleaner is a hydraulic tool developed to meet the specific requirements of ballast tamping on railways. Designed to fit rail-road excavators from 16 to 22 tonnes, it offers an excellent balance of precision, durability, and safety.

Description

Ballast cleaners are ideal for ballast tamping and sleeper preparation. These machines adapt to a wide range of railway applications while optimising maintenance productivity and infrastructure durability.Robustness and durabilityManufactured from high-strength steel, ballast cleaners are designed...

Ballast cleaners are ideal for ballast tamping and sleeper preparation. These machines adapt to a wide range of railway applications while optimising maintenance productivity and infrastructure durability.

Robustness and durability

Manufactured from high-strength steel, ballast cleaners are designed to withstand the toughest conditions. Their reinforced structure and protected hydraulic components ensure longevity, even under intensive use, making them a long-term investment for industry professionals.

Precision and efficiency

The hydraulically operated parallel tine system enables precise and uniform ballast cleaning between sleepers. Adjustable working depth and width offer great flexibility, tailored to each type of track. This precision preserves the integrity of rails and sleepers while speeding up maintenance operations.

Safety and productivity

The ergonomic and secure design of these ballast cleaners makes them easy to use and reduces risks for operators, thanks to insulated electrical contacts and rings.

Robustness and durability

Manufactured from high-strength steel, ballast cleaners are designed to withstand the toughest conditions. Their reinforced structure and protected hydraulic components ensure longevity, even under intensive use, making them a long-term investment for industry professionals.

Precision and efficiency

The hydraulically operated parallel tine system enables precise and uniform ballast cleaning between sleepers. Adjustable working depth and width offer great flexibility, tailored to each type of track. This precision preserves the integrity of rails and sleepers while speeding up maintenance operations.

Safety and productivity

The ergonomic and secure design of these ballast cleaners makes them easy to use and reduces risks for operators, thanks to insulated electrical contacts and rings.

Ballast cleaners are ideal for ballast tamping and sleeper preparation. These machines adapt to a wide range of railway applications while optimising maintenance productivity and infrastructure durability.

Robustness and durability

Manufactured from high-strength steel, ballast cleaners are designed to withstand the toughest conditions. Their reinforced structure and protected hydraulic components ensure longevity, even under intensive use, making them a long-term investment for industry professionals.

Precision and efficiency

The hydraulically operated parallel tine system enables precise and uniform ballast cleaning between sleepers. Adjustable working depth and width offer great flexibility, tailored to each type of track. This precision preserves the integrity of rails and sleepers while speeding up maintenance operations.

Safety and productivity

The ergonomic and secure design of these ballast cleaners makes them easy to use and reduces risks for operators, thanks to insulated electrical contacts and rings.

Robustness and durability

Manufactured from high-strength steel, ballast cleaners are designed to withstand the toughest conditions. Their reinforced structure and protected hydraulic components ensure longevity, even under intensive use, making them a long-term investment for industry professionals.

Precision and efficiency

The hydraulically operated parallel tine system enables precise and uniform ballast cleaning between sleepers. Adjustable working depth and width offer great flexibility, tailored to each type of track. This precision preserves the integrity of rails and sleepers while speeding up maintenance operations.

Safety and productivity

The ergonomic and secure design of these ballast cleaners makes them easy to use and reduces risks for operators, thanks to insulated electrical contacts and rings.

More Information

Specification |

Details |

|---|---|

| SKU | DEGARCASE-3001 |

| Professions | Railway |

| Weight (kg) | 2145 |

| Minimum carrying weight (T) | 16 |

| Maximum carrying weight (T) | 22 |

Get a Quote for

Loading...

Are you sure you would like to remove this item from the shopping cart?

This item is a part of the approved quote. Removing it will remove all quote items from the cart.