REF : BBH1300B-GEN

HYDRAULIC CONCRETE PULVERIZER

The BBH1300 hydraulic concrete crusher in its fixed version is designed for excavators from 45 to 65 tonnes. Equipped with an oversized inverted cylinder, a large opening and width of jaws as well as a round cutting system, it guarantees productivity, robustness and precision on demolition and recycling sites.

Description

It is essential to ensure that the selected equipment complies with the manufacturer’s recommendations for your machine.The configurator is available to help you verify compatibility between the attachment and your excavator.Designed for processing reinforced concrete and recovering scrap metal on...

It is essential to ensure that the selected equipment complies with the manufacturer’s recommendations for your machine.

The configurator is available to help you verify compatibility between the attachment and your excavator.

Designed for processing reinforced concrete and recovering scrap metal on site, the BBH shredder combines cutting power, structural strength, and equipment modularity.

On-site productivity

Available with or without rotation (excluding the BBH1000), the BBH is easily mounted on any type of carrier, accepts up to 380 bar of pressure, and boasts a wide jaw opening and width. The standard reversible round cutter and various options guarantee fast and efficient separation of concrete reinforcement.

Robust design and protected components

The design is built for durability: high-strength steel frame, jaws with abrasion-resistant steel reinforcement ranging from 450HB to 600HB, and a reverse cylinder with rod feed. The cast teeth are bolted, interchangeable, and mounted on two levels to improve grip, with a single reference per model. Wear indicators are integrated into the jaw tips.

Scalable Performance

Numerous options are available to adapt to your needs: speed valve or booster to reduce cycle times, Arden Jet system to limit dust, closure plates to adjust particle size.

Technical data and visuals are non-contractual and subject to change without prior notice.

We remain at your disposal for any technical advice by phone at +33 (0)3 24 33 64 32 or by email at commerce@arden-equipment.com.

Arden Equipment cannot be held liable in the event of improper compatibility.

The configurator is available to help you verify compatibility between the attachment and your excavator.

Designed for processing reinforced concrete and recovering scrap metal on site, the BBH shredder combines cutting power, structural strength, and equipment modularity.

On-site productivity

Available with or without rotation (excluding the BBH1000), the BBH is easily mounted on any type of carrier, accepts up to 380 bar of pressure, and boasts a wide jaw opening and width. The standard reversible round cutter and various options guarantee fast and efficient separation of concrete reinforcement.

Robust design and protected components

The design is built for durability: high-strength steel frame, jaws with abrasion-resistant steel reinforcement ranging from 450HB to 600HB, and a reverse cylinder with rod feed. The cast teeth are bolted, interchangeable, and mounted on two levels to improve grip, with a single reference per model. Wear indicators are integrated into the jaw tips.

Scalable Performance

Numerous options are available to adapt to your needs: speed valve or booster to reduce cycle times, Arden Jet system to limit dust, closure plates to adjust particle size.

Technical data and visuals are non-contractual and subject to change without prior notice.

We remain at your disposal for any technical advice by phone at +33 (0)3 24 33 64 32 or by email at commerce@arden-equipment.com.

Arden Equipment cannot be held liable in the event of improper compatibility.

It is essential to ensure that the selected equipment complies with the manufacturer’s recommendations for your machine.

The configurator is available to help you verify compatibility between the attachment and your excavator.

Designed for processing reinforced concrete and recovering scrap metal on site, the BBH shredder combines cutting power, structural strength, and equipment modularity.

On-site productivity

Available with or without rotation (excluding the BBH1000), the BBH is easily mounted on any type of carrier, accepts up to 380 bar of pressure, and boasts a wide jaw opening and width. The standard reversible round cutter and various options guarantee fast and efficient separation of concrete reinforcement.

Robust design and protected components

The design is built for durability: high-strength steel frame, jaws with abrasion-resistant steel reinforcement ranging from 450HB to 600HB, and a reverse cylinder with rod feed. The cast teeth are bolted, interchangeable, and mounted on two levels to improve grip, with a single reference per model. Wear indicators are integrated into the jaw tips.

Scalable Performance

Numerous options are available to adapt to your needs: speed valve or booster to reduce cycle times, Arden Jet system to limit dust, closure plates to adjust particle size.

Technical data and visuals are non-contractual and subject to change without prior notice.

We remain at your disposal for any technical advice by phone at +33 (0)3 24 33 64 32 or by email at commerce@arden-equipment.com.

Arden Equipment cannot be held liable in the event of improper compatibility.

The configurator is available to help you verify compatibility between the attachment and your excavator.

Designed for processing reinforced concrete and recovering scrap metal on site, the BBH shredder combines cutting power, structural strength, and equipment modularity.

On-site productivity

Available with or without rotation (excluding the BBH1000), the BBH is easily mounted on any type of carrier, accepts up to 380 bar of pressure, and boasts a wide jaw opening and width. The standard reversible round cutter and various options guarantee fast and efficient separation of concrete reinforcement.

Robust design and protected components

The design is built for durability: high-strength steel frame, jaws with abrasion-resistant steel reinforcement ranging from 450HB to 600HB, and a reverse cylinder with rod feed. The cast teeth are bolted, interchangeable, and mounted on two levels to improve grip, with a single reference per model. Wear indicators are integrated into the jaw tips.

Scalable Performance

Numerous options are available to adapt to your needs: speed valve or booster to reduce cycle times, Arden Jet system to limit dust, closure plates to adjust particle size.

Technical data and visuals are non-contractual and subject to change without prior notice.

We remain at your disposal for any technical advice by phone at +33 (0)3 24 33 64 32 or by email at commerce@arden-equipment.com.

Arden Equipment cannot be held liable in the event of improper compatibility.

More Information

Specification |

Details |

|---|---|

| SKU | BBH1300B-GEN |

| Professions | Demolition, Recycling |

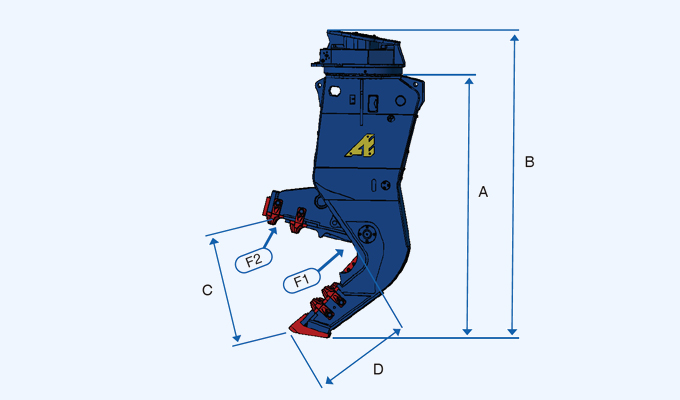

| A (mm) | 3346 |

| C (mm) | 1206 |

| D (mm) | 1381 |

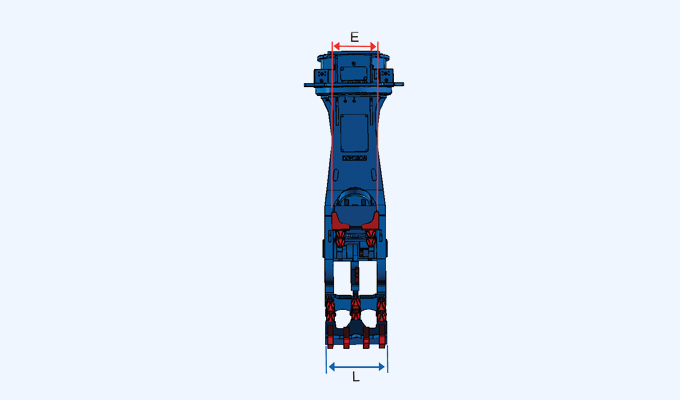

| E (mm) | 575 |

| L (mm) | 840 |

| Force F1 (T) | 688 |

| Force F2 (T) | 151 |

| Round concrete O (mm) | 60 |

| Total cycle time without SV (s) | 9 |

| Total cycle time with SV (s) | 6 |

| Minimum carrying weight (T) | 45 |

| Maximum carrying weight (T) | 65 |

Files

Get a Quote for

Loading...

Are you sure you would like to remove this item from the shopping cart?

This item is a part of the approved quote. Removing it will remove all quote items from the cart.