Véronique Le Provost, new business development for North America at Arden Equipment discusses dust control.

Demolition : New health issues for professionals on outside demolition sites

Last summer massive heat waves hit everywhere on the globe which made it difficult to breathe for the population but even more so for people working on construction and/or demolition sites. However harsh these conditions they have yet to be coupled with the issue of silica dust. Fortunately solutions have been developed and water still represents the most satisfactory alternative for both problems : drink it to hydrate and sprinkle it to reduce dust emission. Simple enough one would say. But with such intense heat inevitably comes water restrictions. It is therefore important to be able to limit water use while achieving maximum dust protection for workers on demolition sites.

Dust control : A more and more challenging issue for contractors

Every year hundreds of construction workers contract or die from respiratory diseases related to silica dust. Federal and State authorities have set up new regulations to help reduce risks, enforcing new standards and in some cases fines can be heavy for non-compliance which could lead to major risks for companies. In addition most bid sponsors now also include specific demands about dust control along with environmental care. Dust control is no longer just a safety and health issue, it has now become a strategic issue to gain a competitive edge.

Solutions exist

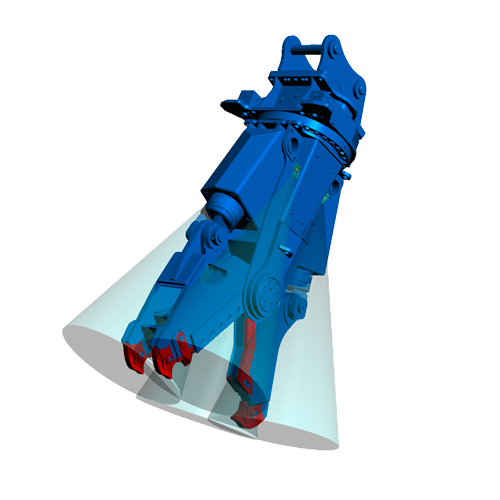

Fortunately contractors haven’t been waiting for new laws to protect their workers and be environmentally friendly. The most standard and effective solution to control dust on outside demolition sites consists in spraying water on the job site. A worker holding a hose in the demolition area or any other independent device spraying water such as water canons are the two basic ways usually used to reduce dust. However, these rather traditional solutions have their own limits : when wind is blowing, when working at height with high reach machines, when visibility from the cabin is limited, when water is contaminated with oil, when cost for new equipments is too high or even when water is restricted to cite the most common ones. A much modern alternative already exists on the market : the ARDEN JET.

Modern solution for modern demolition

Would you like your driver to focus on his demolition job, not on the worker with the hose situated in the danger zone ? Would you like to save on water volume and water treatment ? On maintenance costs ? Would you like to be more environmentally friendly, more cost-effective ? Would you like to surpass your competitors ? If you‘ve ticked at least once then the Arden Jet solution could help you achieve it. With 5 national and international awards, the Arden Jet has already convinced a lot of people!

A technology awarded multiple times!

Awarded 6 times already in France and internationally, the dust solution has already convinced many in the industry.

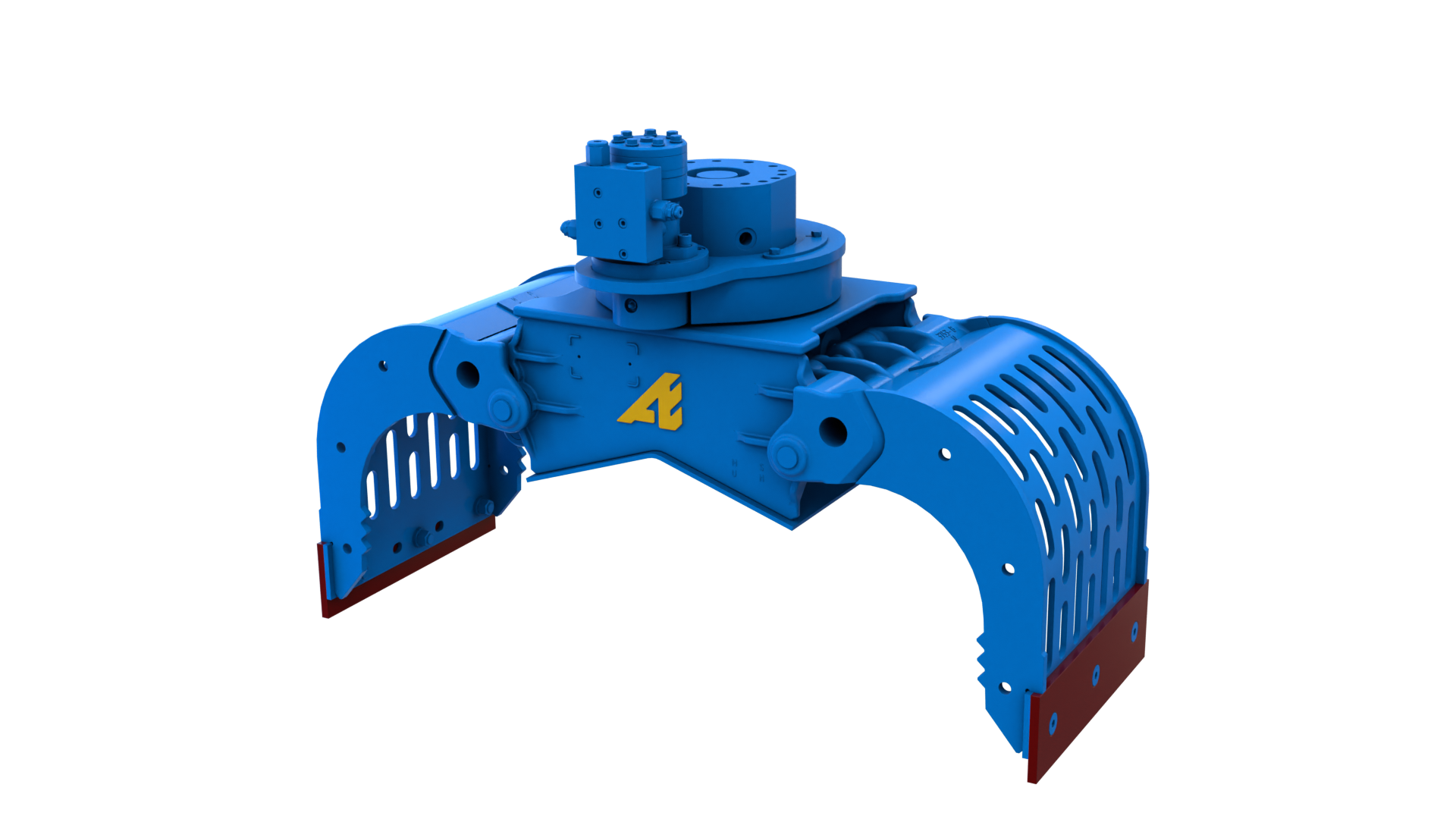

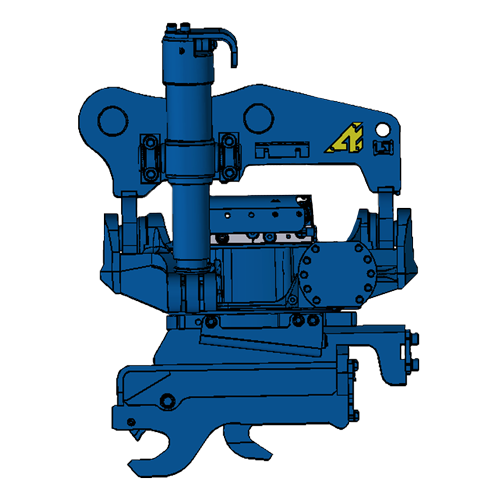

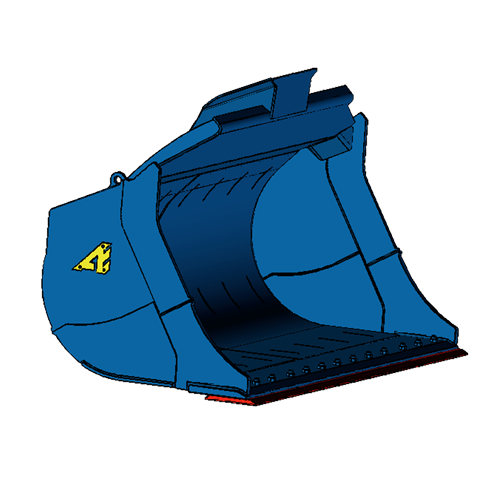

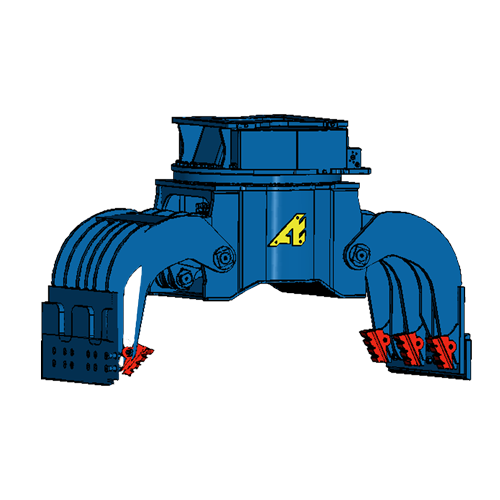

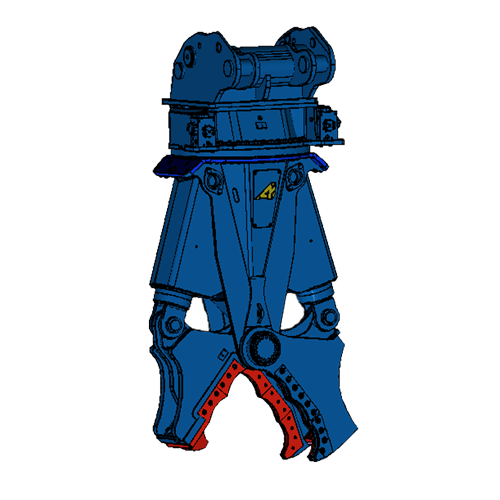

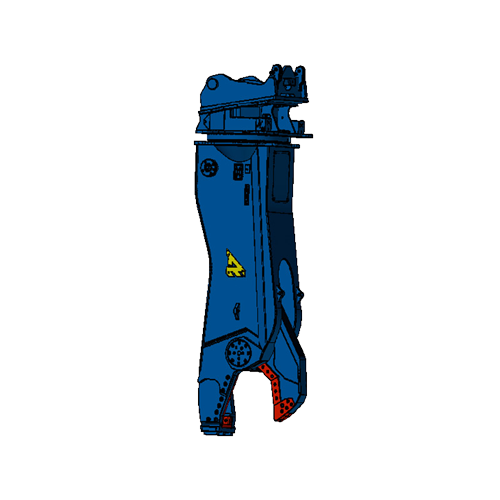

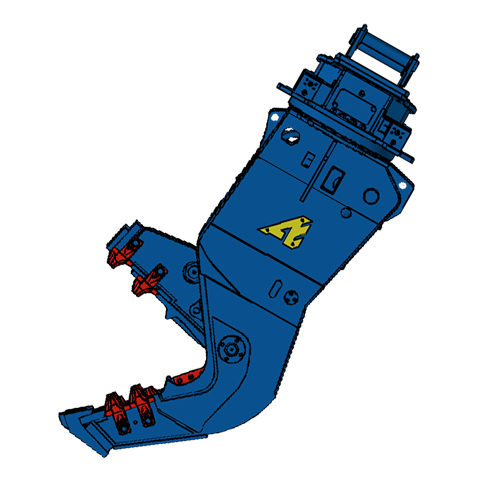

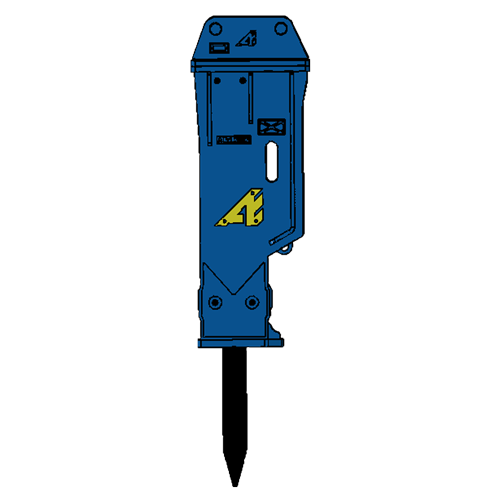

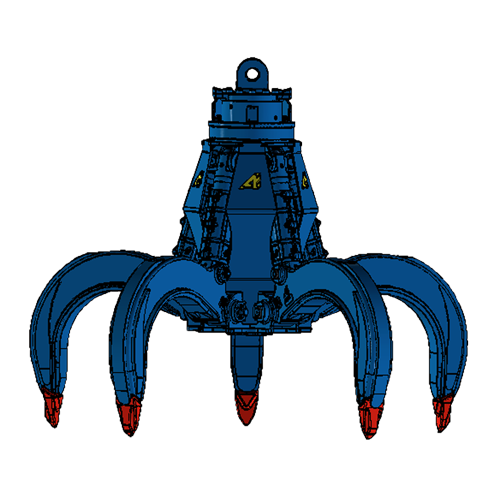

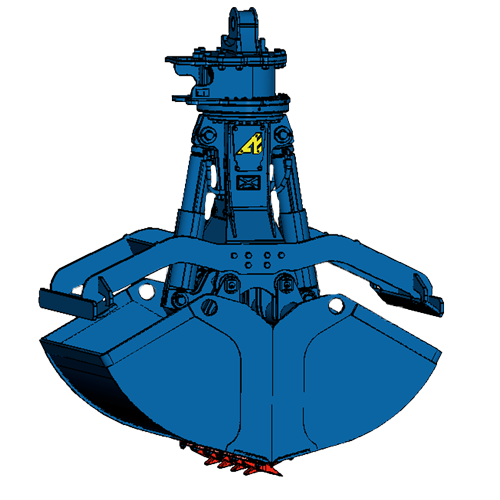

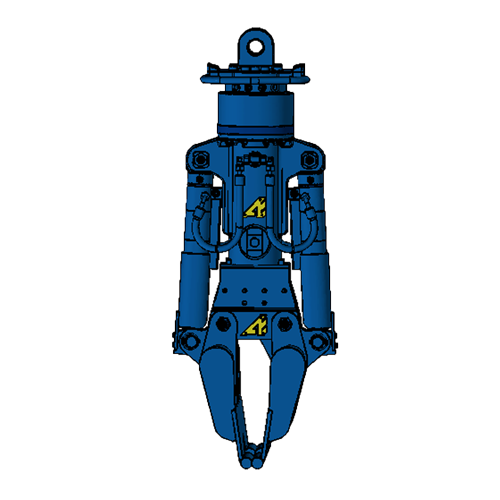

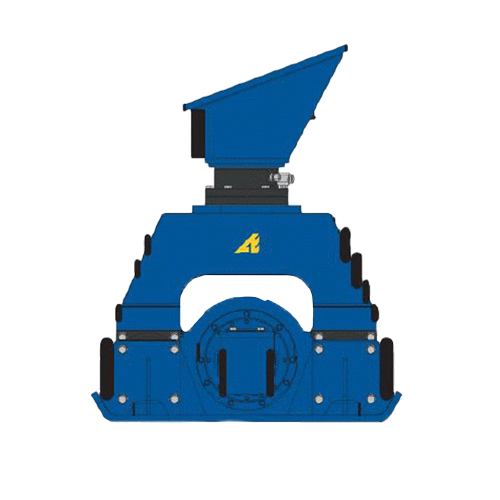

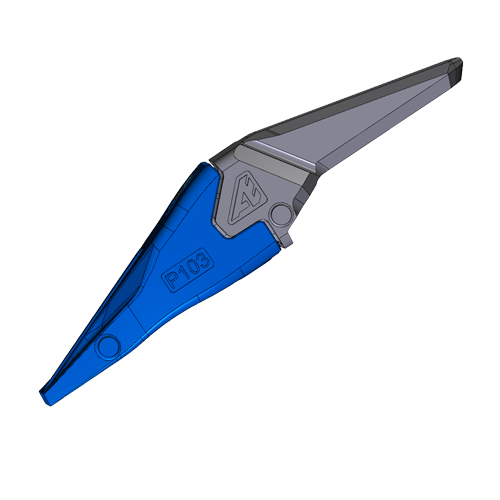

The Arden Jet is the first high pressure water spraying system factory-fitted inside a demolition equipment.

Thank you to all the people who kindly helped me with this article by sharing their experiences about dust control. Special thanks to Jermaine Jennings, Zack Taylor, Jerry Stobaugh, Vincent Mastria, Pete Maginnis, Steve S., Malcom D. Jacobs, Juan Ivanoff and my apologies to those I haven’t mentioned.