Arden'Jet

Arden'Jet

in action

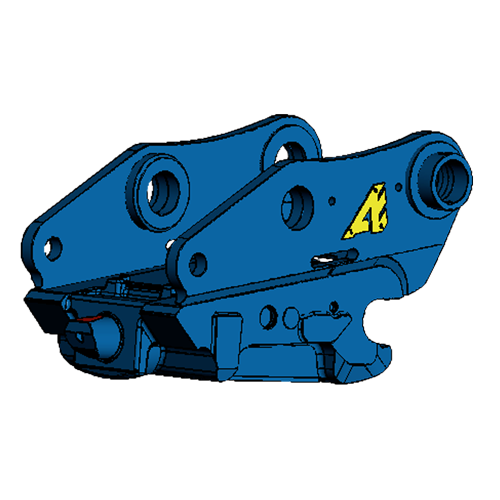

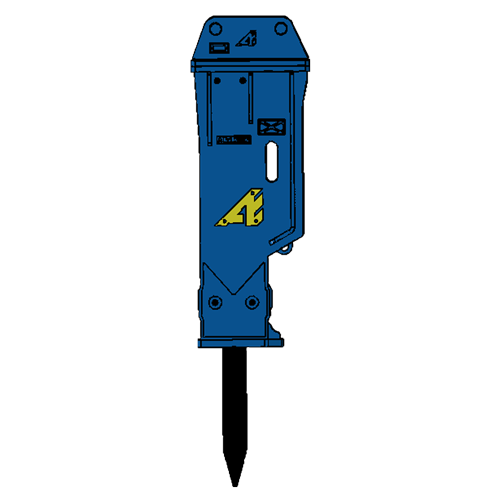

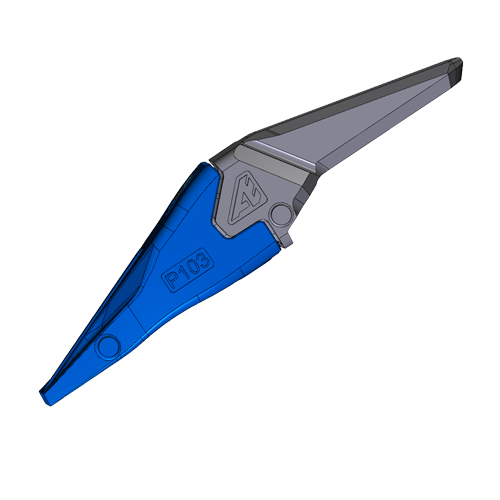

The Arden Jet, an innovation of the French and European leader in demolition, recycling, earthmoving and material handling.

Presentation

Awarded several times worlwide

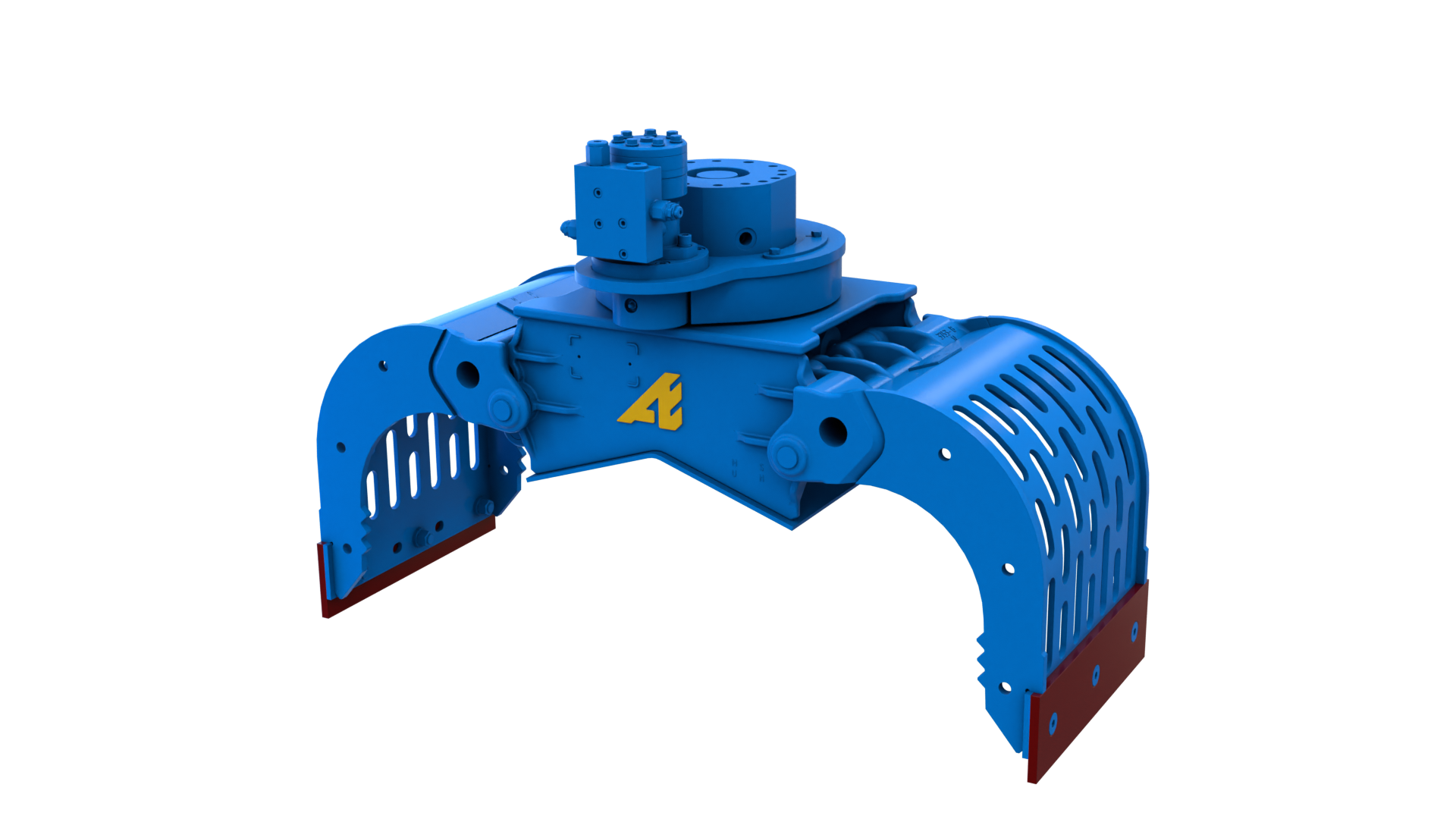

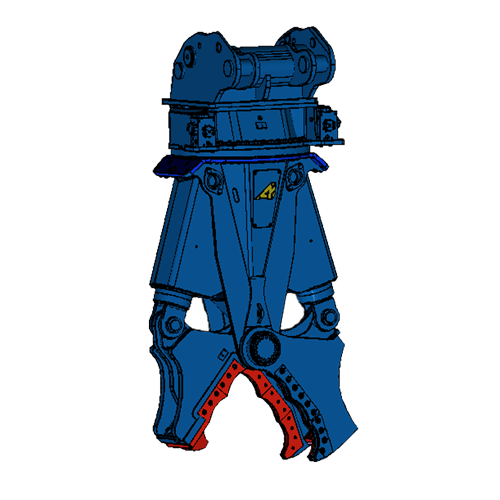

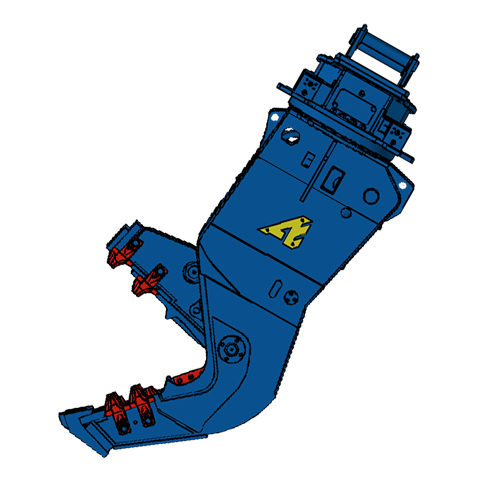

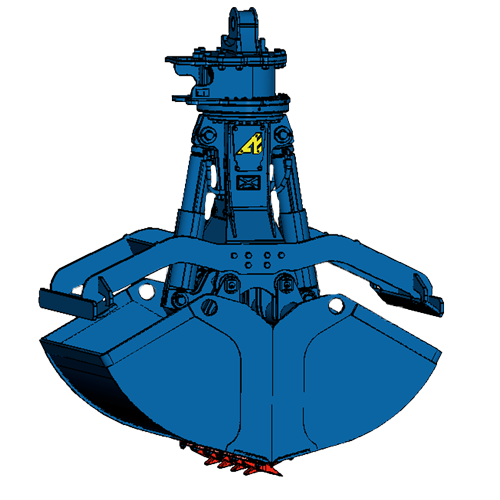

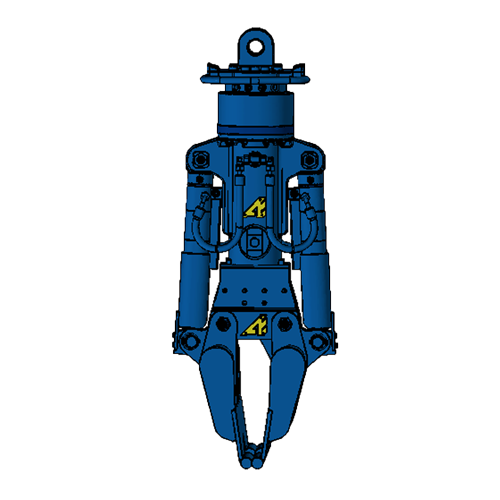

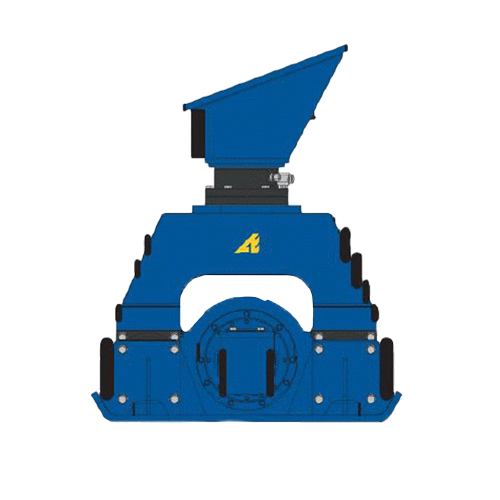

The Arden Jet is the first factory integrated water spray system in a demolition shear that reduces dust and odor emissions.

The technology, awarded 6 times by the demolition industry in France and internationally is ideal to reduce dust on demolition sites or in careers.

Technical characteristics

Hoses system fully integrated inisde the tool

The spraying hoses are fully connected inside the body wich randers them totally invisible and protected from extemal destructive elements. Spraying nozzles can be fitted in different angles or changed by the customer allowing various nozzles diameters and shapes of the spraying pattern to best match job site requirements.

Changing is simple and very quick 360° spraying system via a secured turning joint. The specific turning joint allows hydraulic oil and water management at the same time (no water/oil pollution) enabling the full use of the rotation head to operate the shear without worrying about the hoses position. Hydraulic elements are totaly integrated inside the shear and thus are totally protected. High pressure spraying can operate up to 170 bar.

Better dust suppression control

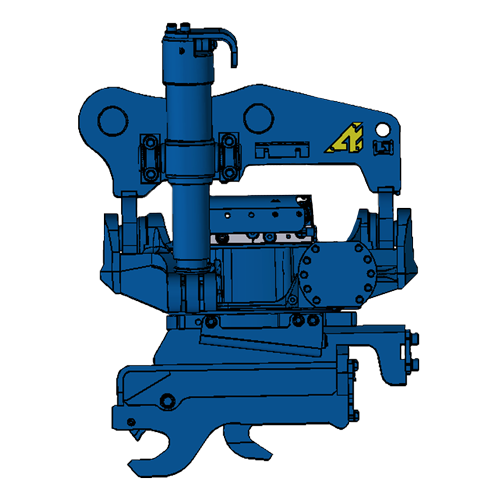

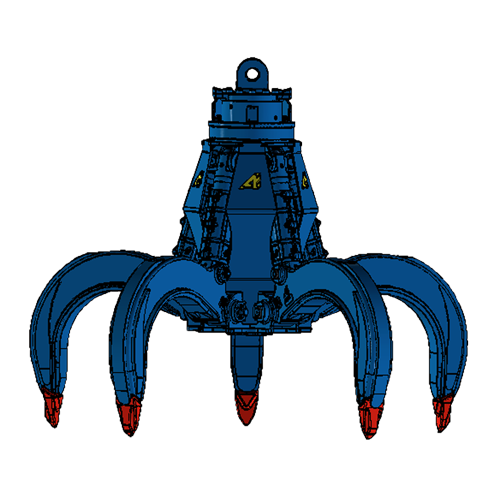

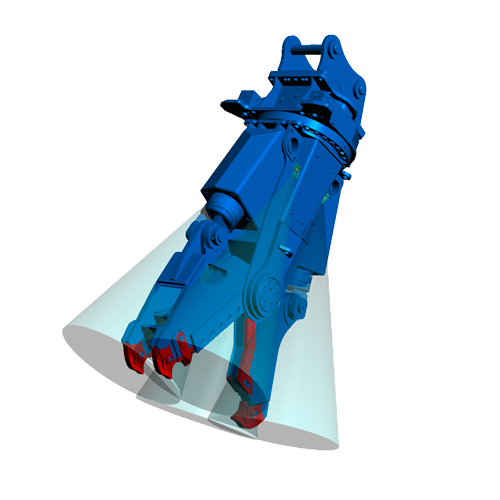

Spraying as close as possible from the area to demolish

High pressurised water turns into a very thin mist that is propelled several meters away creating a large area of fog to better capture airborne particles. The finer water particles are, the better they can capture dust

The use of high pressure water means that less water is necessary for the whole process to be more effective. This means that cost saving on water usage is significant and this is not taking into account cost saving on fuel. The suppresion of dust means also, that other machines around will not be clogged by dust and will therefore run longer and need less maintenance.

The sprayed area is outstandingly accurate because of the four nozzles that are directly fitted on the body of the shear. As water is astomised with high pressure, creating a very fine mist, visibility on demolition area remains very clear.

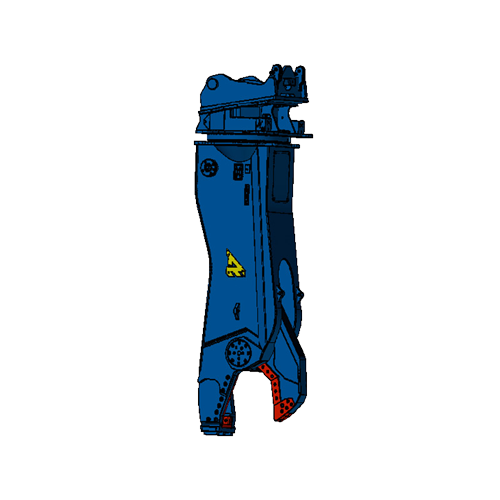

One of the main advantages of Arden Equipment shear is its inverted cylinders in the jaws.This positioning protects effectively the cylinder rods against extemal solid hazards and is even more relevant wiltl the water spraying option as rods are also protected against corrosion.

Health and environmental protection

Environmental protection

It is proved that dust has harmfull impacts on workers and local residents health especially dust particles generated on demolition job sites. The Arden Jet reduces dust particles to bring more safety to workers.

The Arden Jet reduces dramaticaly the mud as water is astomised through the nozzles with high pressure making it very fine mist which is very effective against air borne dust and even micro particles.

Awards received